About

Our family business has been designing and manufacturing tooling for nearly a century. Get quality that’s stood the test of time, with the latest CADCAM technology.

Our family business has been designing and manufacturing tooling for nearly a century. Get quality that’s stood the test of time, with the latest CADCAM technology.

Established for over 90 years, we are a leading supplier of tooling solutions to a range industries.

We are ISO9001 accredited, and use the latest CADCAM technology to produce a range of tooling, principally:

Our 12500ft² facility in the West Midlands is only a short distance from the M6 motorway, and so we are within easy reach of our UK customer base.

As a family-owned and run company we care about the service we provide to our customers. We have a personal, hands-on approach, which means that each tool we manufacture comes with our own stamp of approval.

Your key contacts at Central Patternmaking

Matthew Sawbridge

One of the family and MD for 20+ years

Mark Bannister

An engineer with a passion for people

Mark is your dedicated project manager for fixtures and mould tooling.

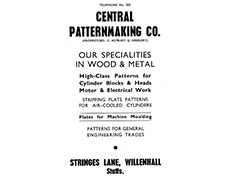

Central Patternmaking Company Limited is formed as subsidiary of

C & L Hill Limited

Patterns for General Engineering Trades

The company makes a profit of £478!

The business assets are bought by John Sawbridge and Arthur Healey, who continue trading as Central Patternmaking

The company is incorporated as Sawbridge and Healey Limited

The company changes its name to Sawbridge and Healey (Central Patternmaking) Limited

John Sawbridge acquires full ownership of the business and the company is renamed as Central Patternmaking Limited

The company invests in its first CNC machine, a Bridgeport Interact 1 Mk 2

CADCAM is introduced into Central Patternmaking as it purchases its first seats of PowerSHAPE and PowerMILL by Delcam.

The company invests in its first high-speed CNC, a Bridgeport VMC1000

John Sawbridge passes away later that year

A Stiefelmeyer Minicheck B becomes the company's first CMM, allowing patterns to be inspected directly against CAD models

The company gains accreditation to ISO9002:1994

The company gains accreditation to ISO9002:1994

The company relocates to its current 11500 ft² premises, still on Stringes Lane.

Alan Sowerby is appointed Sales Manager, and the company embarks upon diversification into the mould tool and jigs and fixtures markets.

The company is accredited to the updated quality standard ISO9001:2008

The company makes its first investment in 5 axis CNC machining, purchasing a CMS Antares

The company makes its first investment in 5 axis CNC machining, purchasing a CMS Antares

The company acquires a Mazak 630 Variaxis II 5 axis CNC machine

The company acquires its second Mazak 630 Variaxis II 5 axis CNC machine

A third Mazak 5 axis CNC machine is commisioned, a Variaxis J600 5X

The company invests in its second inspection arm, a Faro Edge with integrated laser scanner

A third Quaser 3 axis CNC machine is commissioned, an MV184P with a Heidenhain 640 control

Our largest 3 axis CNC is installed - a Quaser MV214P with a stroke of 1524 x 700 x 510

Central Patternmaking, the largest supplier of tooling to the Castings PLC Group, continues to raise its game with the highest standards, attention to detail and ever decreasing lead times that we demand.

- Glen Elmy, Local Director, Castings PLC

Central Patternmaking have been a supplier for Sanko Gosei for many years. A brilliant team of experts who are willing to go beyond expectations to support their customers.

- Vithuran Rasamanikkam, Project Engineer, SET Europe Ltd

We have worked with Matt & the team on a number bespoke engineering projects. We have been extremely pleased with the quality of workmanship and professionalism, and will continue to use Central Patternmaking as one of our preferred suppliers.

- Rob Barnes, Engineering Sales Manager, UK Loco Ltd

“There are a number of businesses which possess similar capabilities but very few that provide the level of differentiation we require. Central Patternmaking is one of those businesses. CPM has turned into a ‘go-to’ business for us. This has been particularly beneficial over the past year when material supplies, skilled resources and general capacity requirements have meant many businesses similar to us have not been able to deliver the results we have been able to. Being able to differentiate yourself as a premium composite component manufacturer requires a robust, reliable, agile and quality supply chain, CPM is just that.”

- Rowan Carstensen, Operations Manager, Prodrive Composites

“Central Patternmaking were the first company entered onto our approved suppliers list when Karma Composites was set up in 2019 based on a 10+ year relationship from previous employment. When dealing with Central Patternmaking it always feels like friends working together to achieve the highest quality possible. The accuracy, quality and all round service from Central Patternmaking is truly outstanding and they’ve never failed to deliver.”

- Adam Smith, Director, Karma Composites